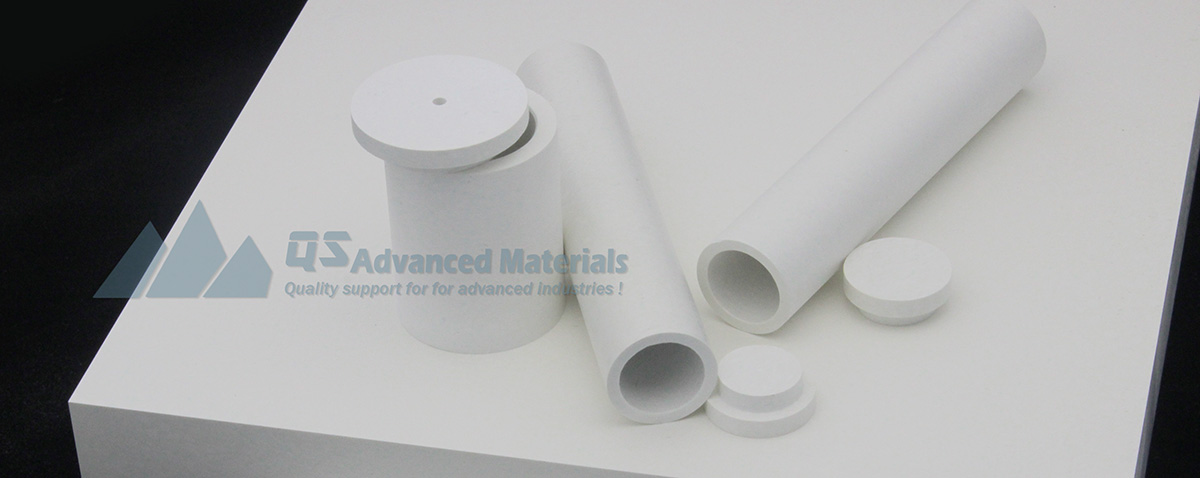

QSAM’s boron nitride plates

Boron nitride plates/sheets conduct heat efficiently. With a thermal conductivity over 30 W/mK, sometimes even higher, they transfer heat well. Additionally, their Mohs hardness of 4 allows for easy machining. This allows them to be easily processed. Further, their electrical insulation properties offer reliable performance. Their low coefficient of thermal expansion also ensures excellent resistance to thermal shocks.

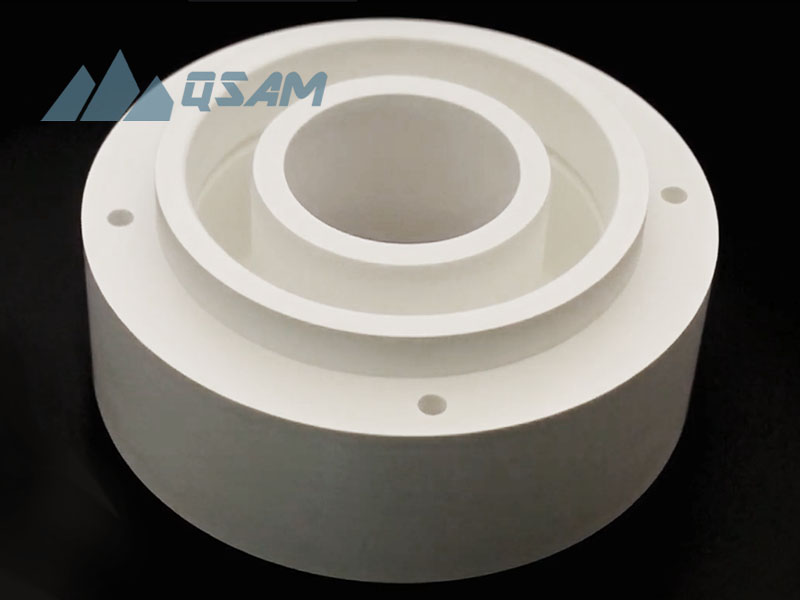

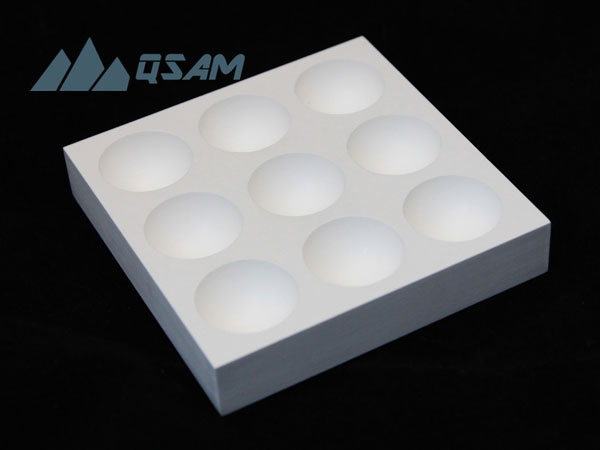

Our boron nitride plates/sheets find various applications. In industries such as metallurgy and electrical engineering, they serve versatile purposes. For instance, they can be used as durable high-temperature furnace materials. Alternatively, they work as crucibles or insulation materials. This provides reliable protection for equipment.

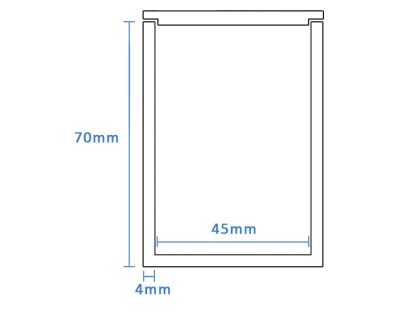

At QS Advanced Materials Inc., we take pride in our advanced hot pressing equipment. This equipment sinters boron nitride slabs in different sizes. Then, we promptly cut these materials into plates or sheets. Another option is to directly use them as supports or insulation. Furthermore, our plates reach up to 16”x16”x8”. This exceeds competitors’ products and allows manufacturing larger components.

Our high-purity boron nitride plates (TPBN) achieve over 99.5% purity. This purity ensures excellent performance and reliability even under strict usage conditions. It meets the needs of demanding applications.

With our boron nitride plate/sheet products, you benefit from versatility, quality, and durability. Whether you require furnace, crucible or insulation materials, our products cater to your needs precisely. Trust our expertise and production to supply the finest quality boron nitride plates/sheets.

Material Grades for our boron nitride plates

BN99:

It is the regular pure material, with a little bit CaO (about 0.5%) as sintering binder. With BN purity better than 99%, it is pure enough and strong enough for most applications, with economic efficiency.

TPBN:

This is our high purity boron nitride material. We also make it with hot pressing. TPBN is more expensive than BN99. In additionally, it has lower density and strength than BN99. However, it provides high purity of over 99.5% (Typical value 99.7%). It has very little calcium impurity. Because of the high purity, TPBN is the ideal material for high purity metallurgy, especially those sensitive to calcium impurities. The high purity makes it good for those uses needing very clean boron nitride. While costing more, the purity may be worth it for sensitive needs.

Boron nitride ceramic introduction

Hot pressed hexagonal boron nitride ceramic is a type of boron nitride material. It is very well known due to its great qualities and many uses. Boron nitride ceramic has a hexagonal crystal structure. This gives it special properties. It conducts heat well and does not conduct electricity. Also, it does not react with other materials.

One useful type is called machinable boron nitride ceramic. Engineers designed it to be easy to shape. This allows fast creation of different forms. Its versatility allows use in many industries. For example, aerospace, automotive and electronics. Because of its unique mix of properties and ease of machining, it is a good choice. It can precisely meet the different needs of industries.

Reviews

There are no reviews yet.